Sustainable drying of water damage

Water damage restoration by ISOTEC:

The cause: Damp screed insulation layer underneath the screed

Moisture penetration is usually caused by water damages or deficient sealing. Warmth and humidity offer the ideal prerequisites for the formation of mould. It may appear after only 10-14 days. For this reason, it is important to dry the damp insulation layer as fast as possible.

01 Installing the air intake hoses

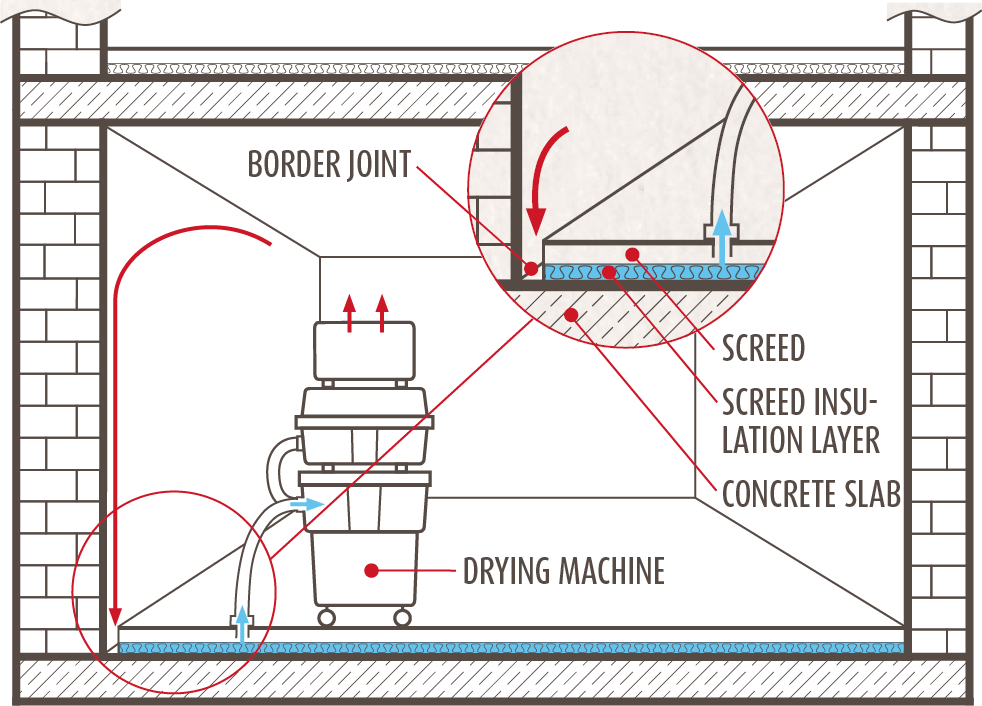

With our drying system, air is drawn in via hoses from the soaked screed insulation layer. Either via the edge joints or via special air intake openings.

02 Dry screed

Condensate dryers dry the air which will then be blowed underneath the screed via screed border joints. The dry air absorbs the moisture of the insulation layer and all cavities underneath the screed. The drying machine then purifies the air in several steps.

03 Control/Measure

Our ISOTEC Drying System reliably eliminates the moisture of the insulation layer underneath the floating screed. Through regular controls we determine the state of the drying process.

Our satisfied customers

Building drying

Building drying via the suction method

Mould may emerge underneath the insulation layer after just 10 to 14 days. This presents a potential health risk to everyone using this space. In order to minimize the microbial contamination, we generally apply our intake method for the drying of water damages.

In order to prevent any additional contamination of the area which needs to be renovated, the drying machine immediately purifies the air intake through several filters (amongst others, HEPA filter). Those filters eliminate spores and other mould components from the air up to 0,001mm. The purified air is then returned to the room where it is dried through a condensate dryer.

Water damage? Learn about our immediate measures

First, the water that has entered the building should be pumped off the surfaces and mopped up. At the same time, the cause of the water penetration should be stopped immediately. However, if a leak or a leakage is not directly visible on the surfaces, the cause of the damage should be remedied promptly before the technical drying measure. What caused the water damage? An expert in damp and mould damage will tell you more about the cause, the damage repair and the costs. Drying should then begin as soon as possible, as experience shows that microbial infestation can develop on surfaces and in damp building components after 10 to 14 days.

Do you have water damage?

Contact us to find out more about the possibilities of drying in the event of water damage and thus avoid further damage and increased costs due to microbial infestation.

Your advantages at a glance

- Sound and heat insulation function of the screed insulation layer is restored

- Preservation of the floor covering possible

- Tested materials

- Fast and safe drying

- Preventive measure to prevent mould or bacterial growth

- This procedure is also recommended in the "Mould Remediation Guidelines" of the Federal Environment Agency

- Prevention of the spread of mould spores

FAQs Drying

What does drying at ISOTEC involve?

We advise you in detail, install the drying systems at your premises and continuously measure the drying progress. At the same time, we prevent the spread of mould and initiate preventive measures.

How can you tell that the masonry is dry?

To ensure this, regular checks are carried out during the drying process, during which we measure how dry the masonry already is. We can determine precisely when the masonry is completely dry.