The problem: salts in the masonry

If the basement walls have been subsequently sealed - whether by means of an exterior waterproofing or a horizontal barrier - you naturally want to use the newly gained space as quickly as possible. It is therefore recommended to apply the ISOTEC renovation plaster system to the inner wall surfaces. The ISOTEC renovation plaster is able to absorb salts and allows moisture to diffuse out of the masonry. Our procedure for applying the restoration plaster is as follows:

The problem: Peeling plaster caused by salts

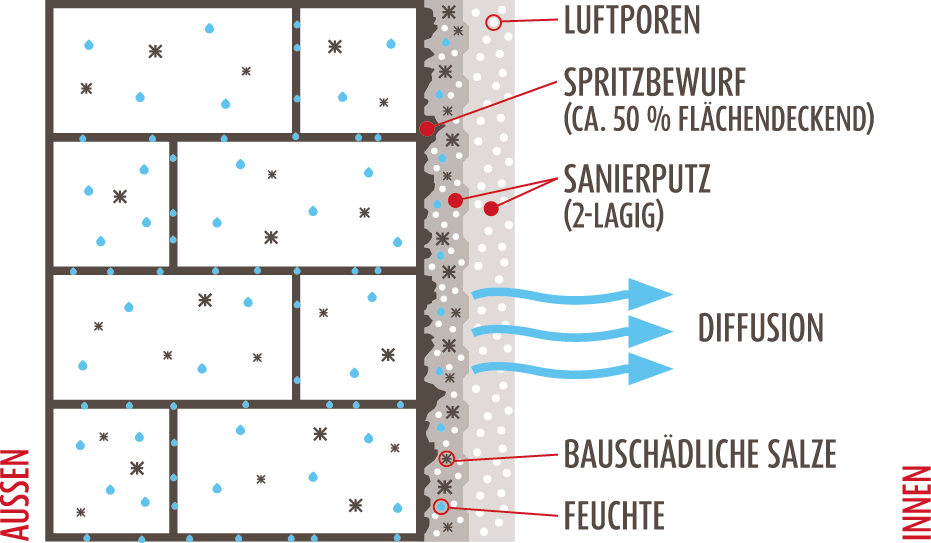

The salts are transported into the existent plaster through capillary moisture. With the evaporation of the moisture, they may crystallize and, by crystalline pressure, cause further peeling of the plaster. Our ISOTEC Renovation Plaster surrounds the salts, prevents further peeling and permits the masonry to dry.

01 Preparing the wall

Initially, we remove existing coats of paint, plaster and other disturbing materials from the masonry. This measure also removes most of the damaging salts. We then prepare the masonry for the application of the rough cast.

02 Optimise adhesion to the masonry

Perfect adhesion of the renovation plaster on the masonry is imperative for a permanent renovation success. For this reason, we apply a roughcast for better adhesion before our ISOTEC Renovation Plaster. This is done in a net-like manner in order to ensure an excellent adhesion of the renovation plaster.

03 Plastering

At last, we apply our ISOTEC Renovation Plaster to the wall. Depending on the degree of salinity, the plaster is applied in one or two coats. Due to its diffusion capacity, the ISOTEC Renovation Plaster ensures the drying of the residual moisture of the masonry.

ISOTEC-Quality

At ISOTEC we use only systems that have passed the most rigid tests and fulfil all requirements. The WTA (German scientific-technical consortium for the preservation of buildings and monuments) has confirmed that our ISOTEC Renovation Plaster fulfils all the test criteria for renovation plaster systems.

![[Translate to Englisch:] Wissenschaftlich-Technische Arbeitsgemeinschaft für Bauwerkserhaltung und Denkmalpflege e.V. [Translate to Englisch:] Wissenschaftlich-Technische Arbeitsgemeinschaft für Bauwerkserhaltung und Denkmalpflege e.V.](/fileadmin/user_upload/Content-XXL-Redakteur/logo8.png)

Your advantages at a glance

- Damage-free drying of the masonry

- Rapid use of the renovated rooms

- Improved living climate

- Increase in the value of the property

- Absorption of salts and binding below the surface

- Visual enhancement

Our satisfied customers

Renovation of the historic vicarage with ISOTEC renovation plaster

ISOTEC Renovation Plaster

Although the source of the moisture damage has been removed, it will take a while for the masonry to dry completely. Depending on the type of masonry and the ventilation, it can take up to two years for the moisture within the cross-sectional area of the wall to completely dry. The high air void ratio of our ISOTEC Renovation Plaster permits the crystallization of salts during the drying phase without causing any damage. For this reason, the renovated space may already be used again during the drying phase.